TEMPORITI MANYETİK FRENLER

| ||

Temporiti s.r.l. 1965 yılından beri elektromagnetik frenlerin üreticisidir.

Temporiti s.r.l. operates since 1965 in manufacturing of electromagnetic fail-safe brakes. The complete knowledge of all the technical aspects of the product and the efficiency of the production capacity allow our company to make different kinds of electromagnetic brakes according to the possible applications.

The company actually operates in two manufacturing plants holding about 1500 mq each, where are made, respectively, the machining and assembling of the product and the electrical parts of the brake.

The company actually operates in two manufacturing plants holding about 1500 mq each, where are made, respectively, the machining and assembling of the product and the electrical parts of the brake.

Temporiti s.r.l. is certified with quality system ISO-9001 since 2001. Our technical department has been developping during the last years new products such as brake models KL, KF, Lift, K for theather and the  antideflagrating brake have made a full analisys on the existing product in order to improve their quality and performances. For this reason Temporiti S.r.l. can offer a complete range of reliable products with the aim to make your products the most competitive on the market.

antideflagrating brake have made a full analisys on the existing product in order to improve their quality and performances. For this reason Temporiti S.r.l. can offer a complete range of reliable products with the aim to make your products the most competitive on the market.

DOĞRU AKIMLA ÇALIŞAN FRENLER

|

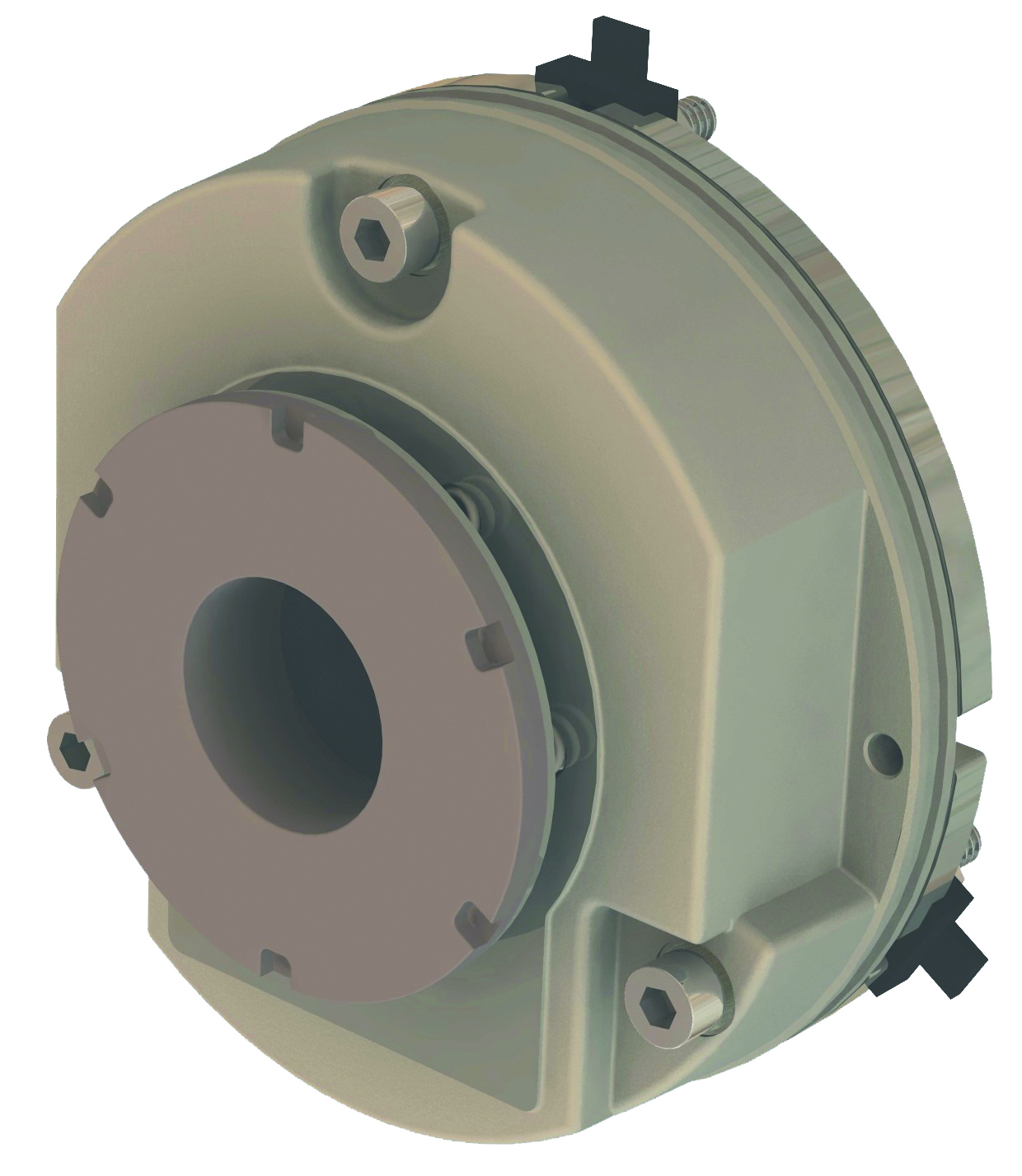

K SERİLERİ

|

K modeli frenler DC yay ile uygulanan serilerdir. Makine millerindeki dairesel hareketin duruşu için tasarlanmışlardır.

NEMA SERİLERİ

|

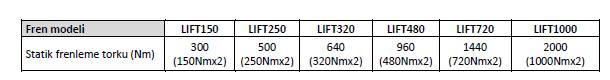

LIFT SERİLERİ

|

Doğru akımla beslenen basınçlı yay frenli olan LIFT serileri elektromekanik modelllerdir.

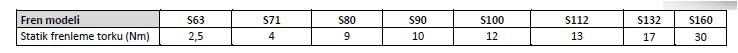

S SERİLERİ

|

S-SH serileri makine milinin dönme hareketini durdurmak amaçlı tasarlanmış yaylı ve DC ile güç ile kontrol edilen modellerdir.

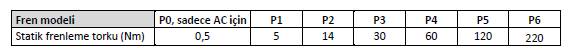

P SERİLERİ

|

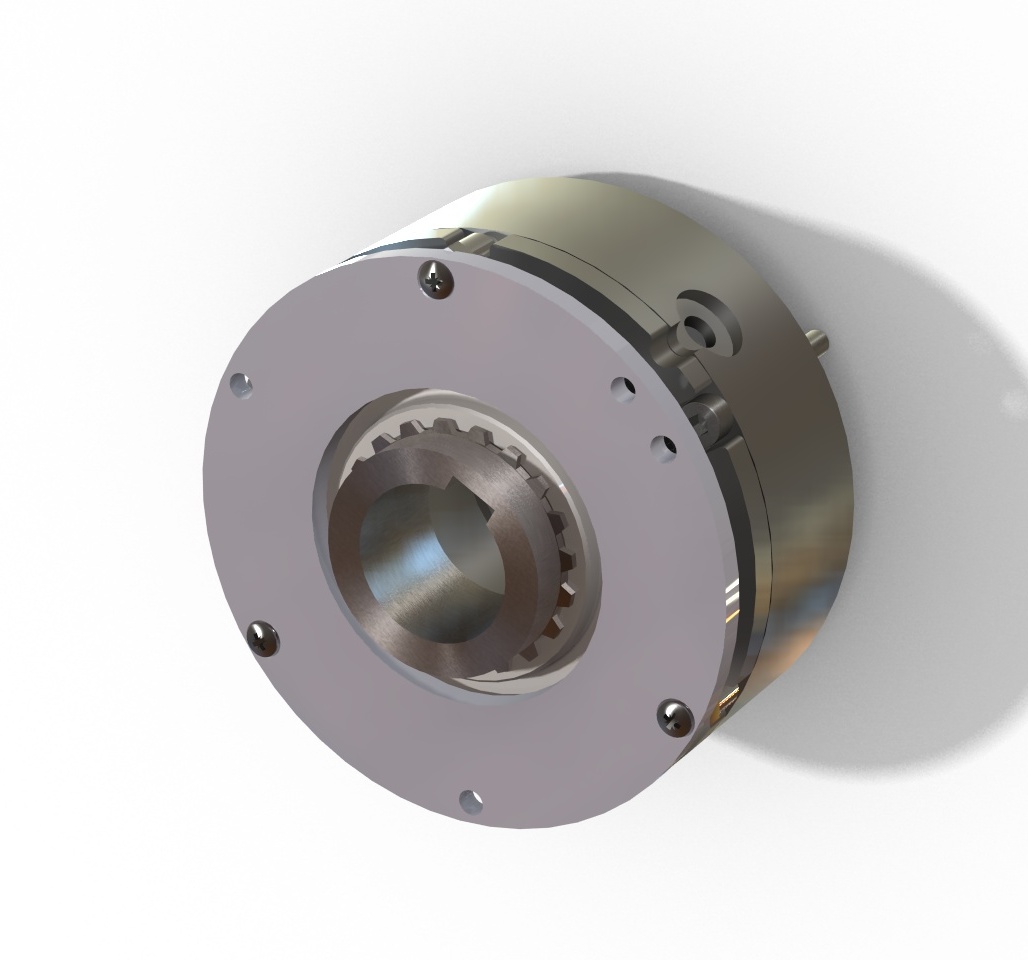

V SERİLERİ

|

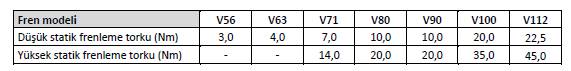

Characteristics of model “V”

V serileri makine milinin dönme hareketini durdurmak amaçlı tasarlanmış yaylı ve DC ile güç ile kontrol edilen modellerdir. / The brake model V is a spring applied power release dc brake which has been designed to stop rotational movement of machine shaft. Proper working order of the brake is guaranteed by following the instructions indicated in this catalogue in the paragraph "Choice of the brake".

Genel özellikleri / General characteristics are:

• Çok sağlam bir yapısı vardır. / Very strong structure;

• Montajı son derece kolaydır. / Very simple in assembling;

•Son derece sessiz çalışırlar. (<70 dBa, 98/37/EEC düzenlemesine göre). / Very quiet in operating (< 70dBA according to Regulation 98/37/EEC);

• Yüskek frenleme torkuna sahiptirler. VH modeli kısmen High braking torque. Particularly model VH allows to obtain high braking torques for a dc brake of such sizes.

V serileri makine milinin dönme hareketini durdurmak amaçlı tasarlanmış yaylı ve DC ile güç ile kontrol edilen modellerdir. / The brake model V is a spring applied power release dc brake which has been designed to stop rotational movement of machine shaft. Proper working order of the brake is guaranteed by following the instructions indicated in this catalogue in the paragraph "Choice of the brake".

Genel özellikleri / General characteristics are:

• Çok sağlam bir yapısı vardır. / Very strong structure;

• Montajı son derece kolaydır. / Very simple in assembling;

•Son derece sessiz çalışırlar. (<70 dBa, 98/37/EEC düzenlemesine göre). / Very quiet in operating (< 70dBA according to Regulation 98/37/EEC);

• Yüskek frenleme torkuna sahiptirler. VH modeli kısmen High braking torque. Particularly model VH allows to obtain high braking torques for a dc brake of such sizes.

V Serisi / Serie V

• Isı dağılımı iyidir. Fan aynı zamanda Good heat dissipation. The fan also acts as braking surface with the advantage to dissipate the heat during brake working and allowing a minimum wear of the friction material;

• The coil is completely encased in epoxy resin ,unless of other construction criteria, and mechanical parts are protected by zinc-plating and painting;

• The brake can be used for several applications with standard motors without using special equipments. It can also work in every position, especially with single phase motors in which there is no vibration of the moving parts.

• The brake is provided with fan cover. Hand release in on request. The balancing of the brake rotating parts is made by Temporiti s.r.l.. Tha balancing of the brake-motor rotating system must be carried out by the motor manufacturer.

• The coil is completely encased in epoxy resin ,unless of other construction criteria, and mechanical parts are protected by zinc-plating and painting;

• The brake can be used for several applications with standard motors without using special equipments. It can also work in every position, especially with single phase motors in which there is no vibration of the moving parts.

• The brake is provided with fan cover. Hand release in on request. The balancing of the brake rotating parts is made by Temporiti s.r.l.. Tha balancing of the brake-motor rotating system must be carried out by the motor manufacturer.

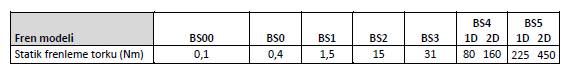

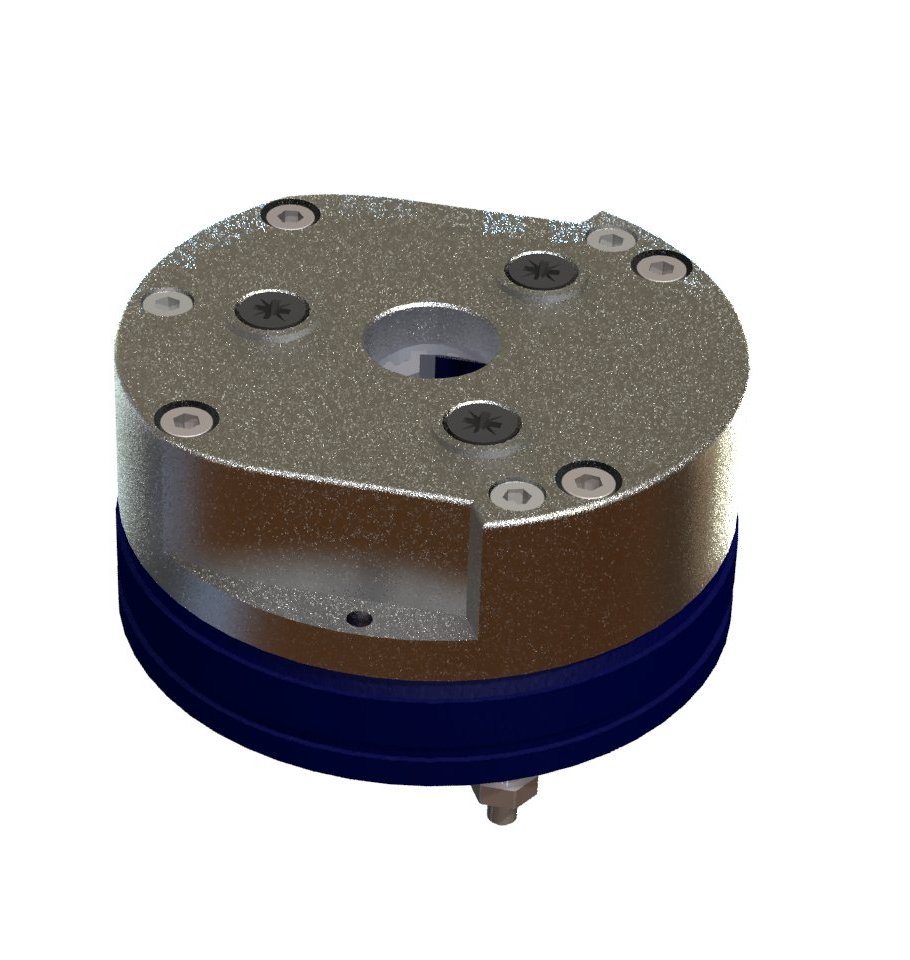

BS SERİLERİ

|

Özellikler/ Characteristics

• Kompakt bir yapıya sahiptirler. Bu tür frenler fırçasız motorlarda kullanıldıkları gibi 120°C sıcaklığa kadar kullanımları mümkündür./Compact structure. These kind of brakes are used on Brushless motors. They can be used untill 120°C.

• Son derece sessiz çalışırlar. (<70 dB, 98/392 CEE düzenlemesine göre) / Very quiet in operation (<70 dB according to Regulation 98/392 CEE).

•Bu fren statik kullanım sistemleri için tasarlanmıştır. 1500 devir/dakikanın altındaki hızlarda güvenle kullanılabilirler. / The brake is designed for a static operation of the system. They can be used for safety braking but with the speed < 1500 rpm.

• Temporiti s.r.l. tarafından tasarımı yapılan bu yeni frenin önceden montajı yapılmıştır. Böylece, frenin This new brake designed by Temporiti s.r.l., is provided already assembled. Therefore the brake is very easy to assemble as the operator must only lock the keyer screws to fit the braking disc.

• The motor cover and the aluminium surface allow a good heat dissipation of both the electromagnet and the braking disc.

• Kompakt bir yapıya sahiptirler. Bu tür frenler fırçasız motorlarda kullanıldıkları gibi 120°C sıcaklığa kadar kullanımları mümkündür./Compact structure. These kind of brakes are used on Brushless motors. They can be used untill 120°C.

• Son derece sessiz çalışırlar. (<70 dB, 98/392 CEE düzenlemesine göre) / Very quiet in operation (<70 dB according to Regulation 98/392 CEE).

•Bu fren statik kullanım sistemleri için tasarlanmıştır. 1500 devir/dakikanın altındaki hızlarda güvenle kullanılabilirler. / The brake is designed for a static operation of the system. They can be used for safety braking but with the speed < 1500 rpm.

• Temporiti s.r.l. tarafından tasarımı yapılan bu yeni frenin önceden montajı yapılmıştır. Böylece, frenin This new brake designed by Temporiti s.r.l., is provided already assembled. Therefore the brake is very easy to assemble as the operator must only lock the keyer screws to fit the braking disc.

• The motor cover and the aluminium surface allow a good heat dissipation of both the electromagnet and the braking disc.

The electromagnet winding is completely encased in epoxy resin ,unless of other construction criteria, and the mechanical parts are protected by a zinc-plating treatment. The structure of the brake allows working in continuous duty without ventilation. Class F Insulation.

• The brake allows to develop a high and steady static torque due to the patented design of the braking system. Any variation of the braking torque is possible by changing the springs load, therefore the torque value doesn't change during the time.

• The brake allows to develop a high and steady static torque due to the patented design of the braking system. Any variation of the braking torque is possible by changing the springs load, therefore the torque value doesn't change during the time.

ALTERNATİF AKIMLA ÇALIŞAN FRENLER

|

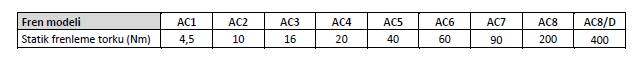

AC SERİLERİ

|

AC serisi frenler yay uygulamalı modellerdir. Makine milinin dönme hareketini AC fren ile durdurmak için tasarlanmışlardır.

NEMA SERİLERİ

|

T-MEC SERİLERİ

|

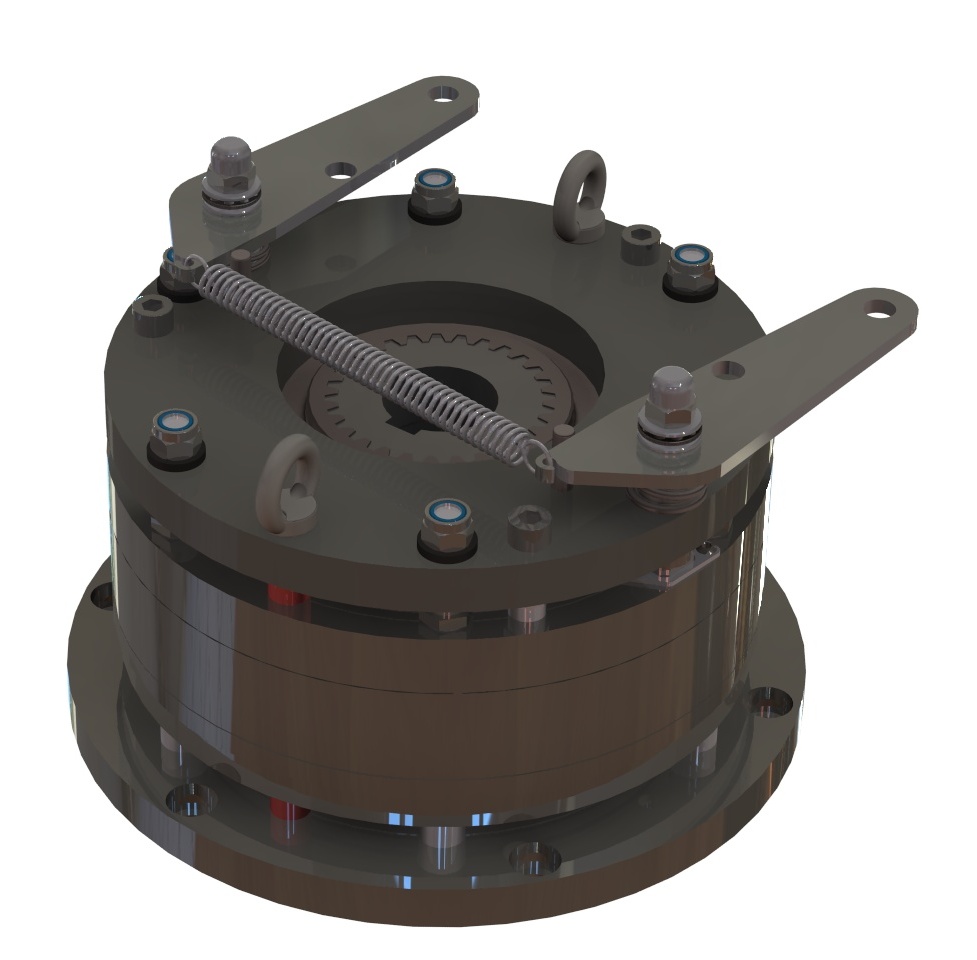

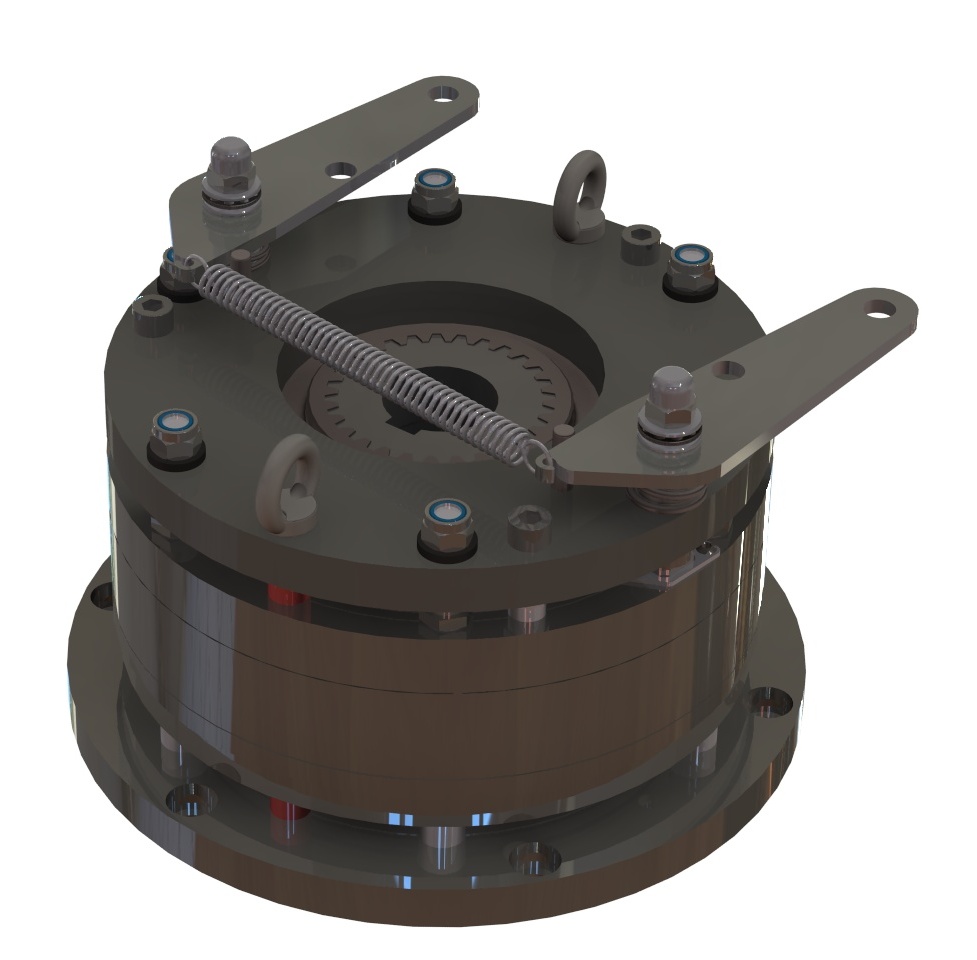

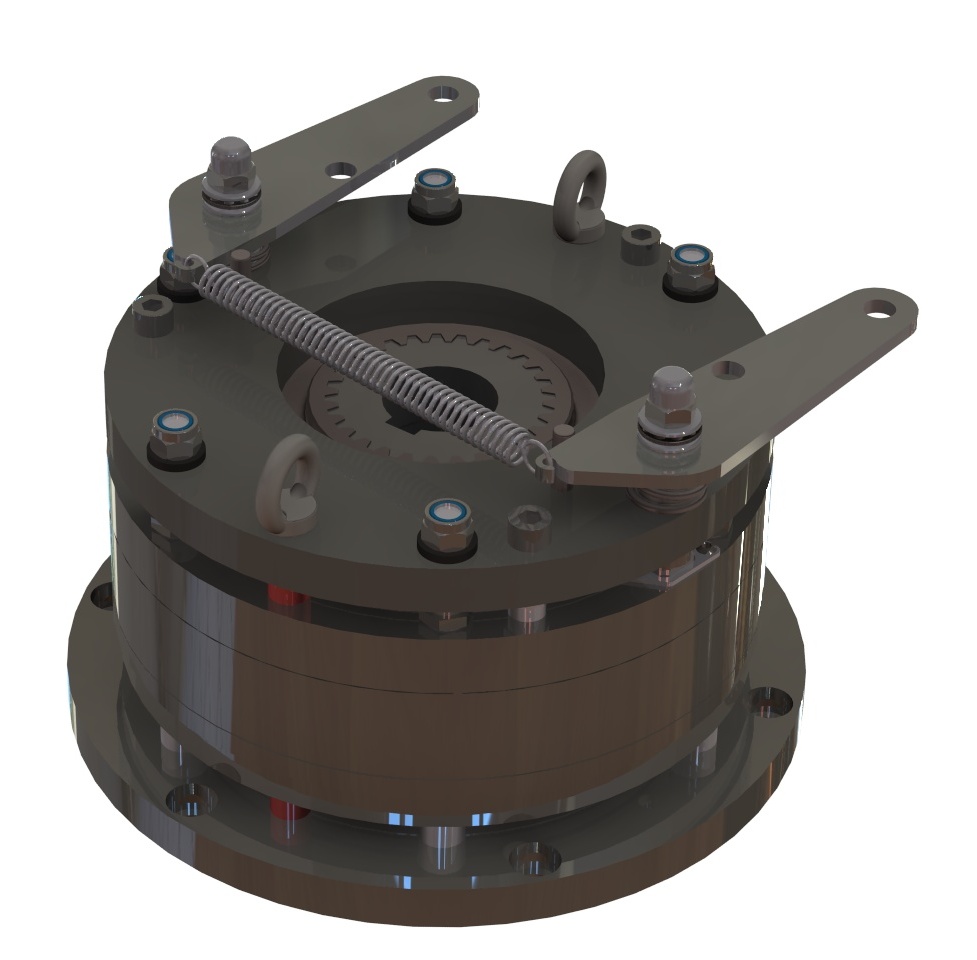

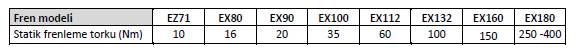

EX SERİLERİ

|

14 Haziran 1989 (89/392/CEE) Avrupa Konseyi direktiflerine hazırlanmış frenler olup, daha ziyade patlayıcı ortamlarda çalışan cihazlar için tasarlanmışlardır.

Hiç yorum yok:

Yorum Gönder